The Essential Role of Bottle Label Applicators in Modern Business

In today's fast-paced commercial environment, businesses are constantly seeking ways to optimize their operations. One critical aspect often overlooked is the labeling process in various industries. The introduction of the bottle label applicator has changed the game, providing businesses with the tools to not only improve efficiency but also enhance product presentation. In this comprehensive guide, we will delve into the importance, benefits, and various applications of bottle label applicators, particularly in the sectors of printing services, electronics, and computers.

Understanding Bottle Label Applicators

A bottle label applicator is a machine designed to automate the process of applying labels to bottles. This equipment serves a crucial function in numerous industries, ranging from beverages to personal care products. The evolution of these machines has led to increased accuracy, consistency, and speed in the labeling process.

Why Are Bottle Label Applicators Essential?

In a landscape where operational efficiency is paramount, businesses must adopt technology that streamlines workflows. Here are several reasons why investing in a bottle label applicator is not just beneficial, but essential:

- Increased Efficiency: Automating the labeling process significantly reduces the time taken to prepare products for sale.

- Consistency: These machines ensure that labels are applied uniformly, reducing the risk of human error.

- Cost-Effectiveness: By minimizing labor costs and maximizing output, businesses can achieve a higher return on investment.

- Improved Brand Image: Professional labeling enhances product appeal and consumer trust.

- Flexibility: Many bottle label applicators can accommodate different bottle shapes, sizes, and label types.

Applications of Bottle Label Applicators in Various Industries

Printing Services

Within the printing services sector, the need for high-quality labels is crucial. Bottle label applicators can streamline the service process, enabling printing businesses to offer faster turnaround times for their clients. By utilizing these machines, printing companies can effectively handle bulk orders for beverage companies, cosmetic lines, and more, leading to enhanced customer satisfaction.

Electronics

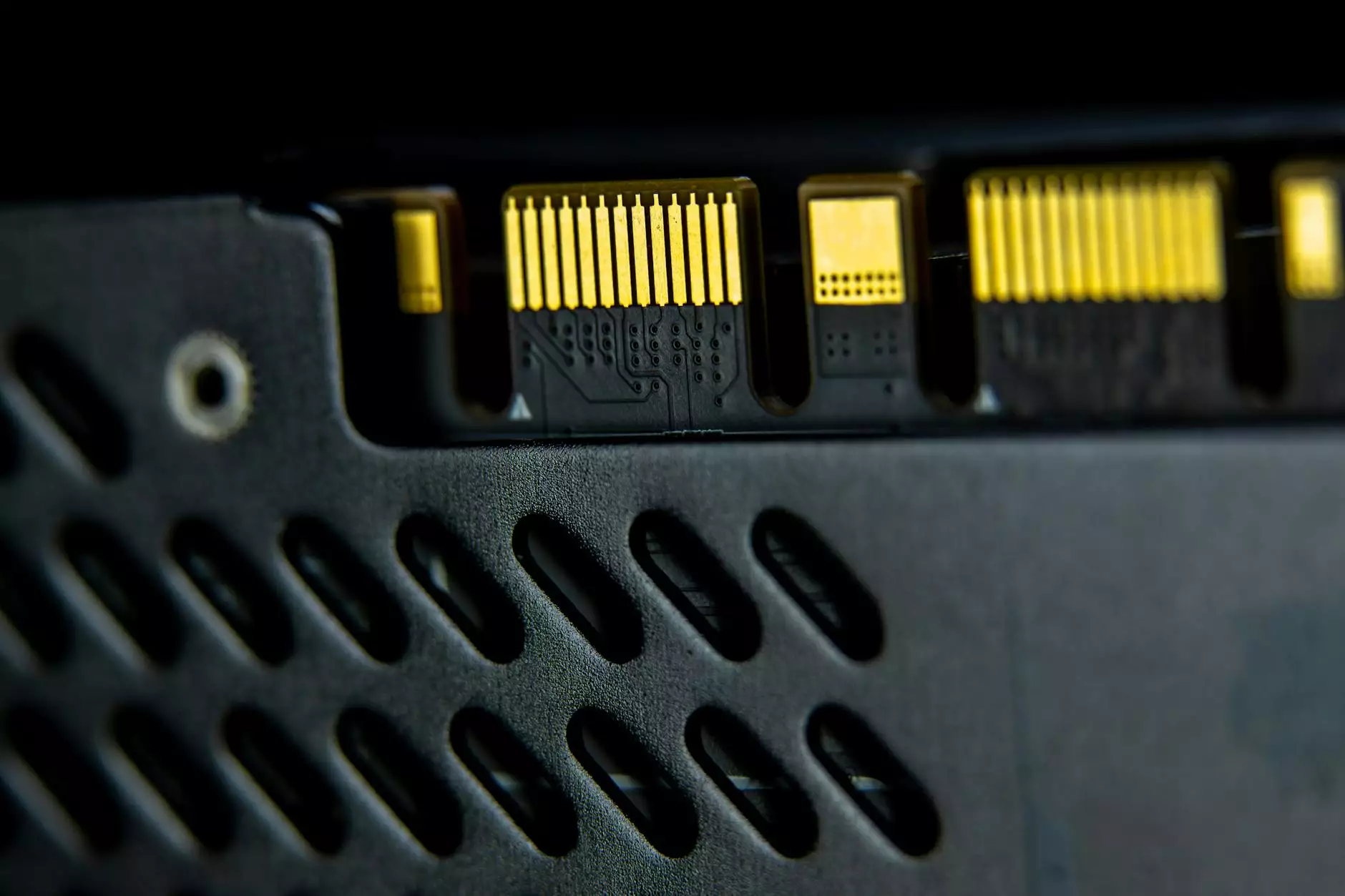

In the electronics industry, clear and precise labeling is a regulatory requirement. Products such as batteries, chargers, and devices must have accurate labels that convey essential information. A bottle label applicator can ensure that these labels are affixed correctly and comply with the relevant standards, improving legal safety and product reliability.

Computers

Just as in electronics, the computer industry requires precise labeling for components such as memory drives and peripherals. Here, bottle label applicators enhance the efficiency of packaging and shipping processes. When labels are consistent and inform the customer about specifications, it reduces confusion and enhances user experience.

Key Features of Modern Bottle Label Applicators

Modern bottle label applicators are equipped with several advanced features that cater to the evolving needs of businesses. Understanding these features can help in making an informed investment decision.

- Speed: Many applicators can apply hundreds of labels per minute.

- Versatility: Ability to handle various bottle shapes and sizes, from cylindrical to square.

- User-Friendly Interface: Most modern label applicators come with intuitive controls, making them easier to operate.

- Integration Capabilities: They can often be integrated with existing production lines.

- Durability: Built to withstand industrial environments while maintaining performance.

Choosing the Right Bottle Label Applicator

Selecting a bottle label applicator that fits your business needs requires careful consideration. Here are some factors to consider when making your choice:

- Production Volume: Consider how many bottles you need to label per hour and choose an applicator that meets those demands.

- Label Type: Ensure compatibility with your labels, including size, material, and adhesive type.

- Future Scalability: Invest in a machine that can adapt to future growth in your business.

- Maintenance: Look for machines that are easy to maintain and have readily available technical support.

- Cost: Balance between cost and features, ensuring you are investing in quality machinery without overspending.

The Impact of Bottle Label Applicators on Branding

Effective branding is critical in today's marketplace, and labeling plays a pivotal role. An attractive label can significantly influence consumer purchasing decisions. Here’s how a bottle label applicator can enhance your branding efforts:

- Quality Presentation: Consistently applied labels reflect professionalism.

- Customizability: Labels can be tailored to match your brand identity, including colors, designs, and materials.

- Information Dissemination: Provides an opportunity to inform consumers about product benefits, enhancing brand trust.

- Regulatory Compliance: Ensures labels meet legal requirements, which is essential for maintaining brand integrity.

Conclusion: Elevating Business Efficiency with Bottle Label Applicators

In conclusion, the implementation of a bottle label applicator can transform the way businesses operate across multiple sectors. By enhancing efficiency, ensuring accuracy, and improving branding opportunities, these machines represent a worthwhile investment for businesses looking to thrive in today's competitive landscape. As the need for speed and professionalism increases, companies must adopt innovative solutions like bottle label applicators to stay ahead.

Whether you are in the printing services, electronics, or computer industries, understanding the benefits and applications of bottle label applicators can significantly impact your overall operational success.

For more insights and premium solutions tailored for your business needs, visit omegabrand.com and explore our extensive range of products and services designed to elevate your operational efficiency.